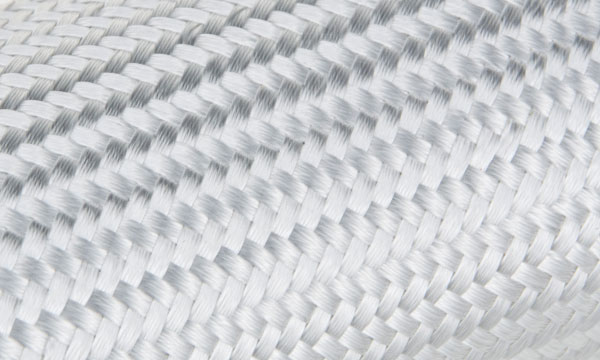

Silica Fiber

◆ Composition and Purity:

◆ Composition and Purity:

Quartz fiber is made from high-purity silicon dioxide (SiO₂) and natural quartz crystals, with a SiO₂ content exceeding 99.95% by mass.

Silica fiber is a type of glass fiber with a SiO₂ content typically above 95% but lower than that of quartz fiber. It is produced using standard glass fiber manufacturing processes.

◆ Physical Properties:

◆ Physical Properties:

Heat Resistance: Quartz fiber possesses excellent heat resistance, with a long-term use temperature up to 1200°C and a softening point as high as 1700°C. This makes it an ideal material for high-temperature applications.

Strength and Stability: Quartz fiber maintains high strength at elevated temperatures, exhibits excellent dimensional stability and has superior thermal shock resistance.

Other Properties: It also has good chemical stability, optical transparency and electrical insulation properties.

Heat Resistance: Silica fiber exhibits good heat resistance and thermal shock resistance, but its performance in extreme temperatures is not as high as that of quartz fiber.

Strength: Due to microdefects and microcracks present in its structure, the tensile strength of high-silica fiber is significantly lower compared to quartz fiber, often only one-fifth of quartz fiber’s strength.

High-Temperature Limitations: When temperatures exceed 982°C, impurities in high-silica fiber can cause crystallization, adversely affecting material properties.

◆ Applications:

◆ Applications:

Quartz fiber finds applications in demanding industries such as military, defense, aerospace, and aviation, where its superior performance is crucial.

Despite its limitations, high-silica fiber is still useful in various applications requiring high-temperature resistance, such as in the production of composites for certain aerospace components and electrical materials. However, its applications may be more limited compared to quartz fiber.

◆ Comparison Summary

Purity: Quartz fiber has a higher SiO₂ content (exceeding 99.95%) compared to silica fiber (typically above 95%).

Strength: Quartz fiber has significantly higher tensile strength than silica fiber, which is often only one-fifth of quartz fiber’s strength.

High-Temperature Performance: Quartz fiber maintains superior performance at extreme temperatures, with a higher long-term use temperature and softening point.

Applications: Quartz fiber finds broader applications in demanding industries due to its superior properties, while silica fiber’s applications may be more limited.

This comparison highlights the key differences between quartz fiber and silica fiber, emphasizing the importance of choosing the appropriate material based on specific application requirements.